How to Use AI in Logistics: Our Step-by-Step Guide to Smarter Supply Chains

Learn how AI is transforming logistics with automation, predictive analytics, and real-time tracking for improved efficiency, cost savings, and smarter decisions.

12th February 2025

Quick Summary

This article explains how AI is revolutionising logistics through technologies like machine learning, predictive analytics, and automation. It highlights the benefits, such as increased efficiency, cost optimisation, and improved visibility. It covers practical steps for integrating AI, including demand forecasting, route optimisation, risk management, and sustainability, with Zeus providing AI-powered solutions.

Ready to Streamline Your Supply Chain with AI?

Artificial intelligence is transforming the logistics industry, and businesses that adopt AI-driven strategies are seeing faster deliveries, cost savings, and improved operational efficiency. The future of logistics lies in smart technologies that optimise routes, predict demand, and automate time-consuming tasks.

In this Zeus article, we are going to explain how AI can be seamlessly integrated into your logistics operations. But first...

Why Listen to Us?

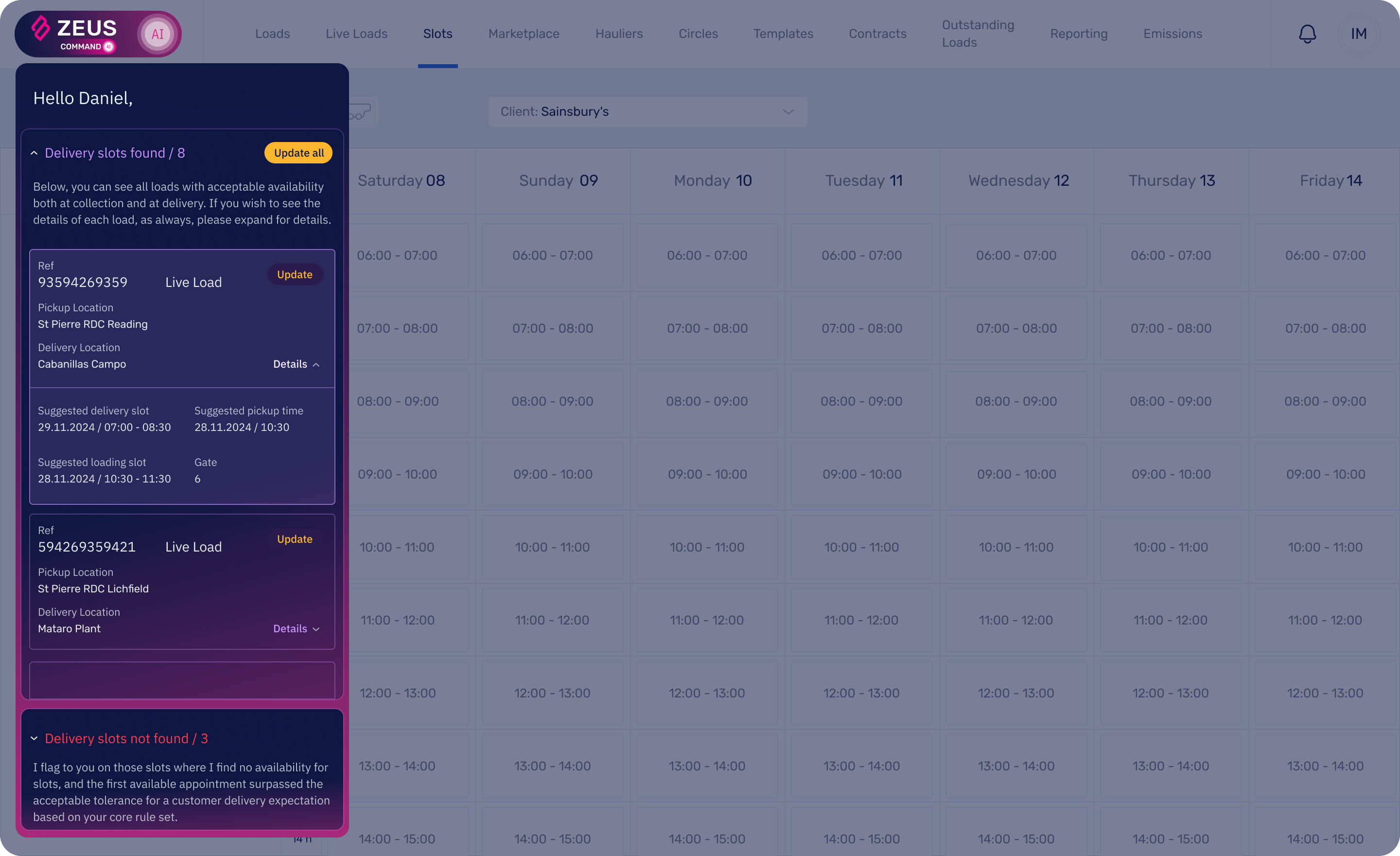

At Zeus, we lead the way in AI-powered logistics solutions that help businesses optimise their supply chains. Our solution Zeus Command AI, using advanced technology to automate processes, reduce costs, and provide real-time insights. Zeus Command AI is an integrated enterprise software platform designed to seamlessly connect with ERP systems, automating freight operations with precision. Powered by advanced AI modules and NVIDIA technology, it delivers accurate predictions, deeper insights, and enhanced control over the supply chain.

Trusted by top global brands like Primark, Decathlon, AB InBev and P&G, we have the expertise to guide you in leveraging AI for smarter, more efficient logistics management.

What is the Role of AI in Logistics?

AI is transforming logistics through technologies like machine learning, predictive analytics, and automation, driving efficiency and innovation across supply chains.

- Machine Learning: This enables systems to learn from historical data, optimising routes, predicting maintenance needs, and forecasting demand trends.

- Predictive Analytics: AI forecasts future events, helping businesses plan resources, manage inventories, and reduce downtime by predicting disruptions.

- Automation: AI automates tasks like inventory tracking, shipment scheduling, and warehouse management, streamlining operations and improving speed.

Benefits of Adopting AI in Logistics

- Increases Operational Efficiency: AI automates manual tasks like freight scheduling, warehouse management, and route planning, reducing errors and speeding up workflows.

- Optimises Costs: AI-powered analytics identify inefficiencies, optimise fuel consumption, and reduce waste, leading to significant cost savings.

- Enhances Supply Chain Visibility: Real-time tracking and predictive analytics improve decision-making, reduce delays, and ensure on-time deliveries.

- Improves Demand Forecasting: AI analyses historical and market data to predict demand fluctuations, preventing stockouts and overstocking.

- Reduces Risks and Disruptions: AI-driven risk analysis identifies potential bottlenecks and recommends proactive solutions to keep operations running smoothly.

How to Use AI in Logistics

1. Identify Key Areas for AI Application

Before implementing AI in logistics, businesses must identify inefficiencies and gaps that AI can address. Pinpointing these issues will define your AI implementation strategy.

This requires a data-driven approach to analyse key logistics pain points, such as freight delays, route inefficiencies, inventory misalignment, and high operational costs.

Start by conducting a supply chain audit, focusing on:

- Freight Management: Are shipments consistently delayed? Are you relying on costly spot-market contracts?

- Warehouse Operations: How often do stockouts or overstocking occur? Are fulfilment speeds meeting demand?

- Route Optimisation: Are fuel costs high due to inefficient routing? Are drivers consistently late?

- Customer Experience: How often are deliveries delayed or misplaced? Do customers receive real-time shipment updates?

2.Choose the Right AI Tools and Technologies

After identifying key pain points in your logistics operations, selecting the right AI tools is crucial to maximising efficiency. Here’s an overview of the most effective AI technologies for logistics:

Machine Learning (ML)

ML helps analyse large datasets to detect patterns and predict future outcomes, like:

- Demand Forecasting: Predict future demand based on historical data.

- Freight Rate Optimisation: Suggest cost-effective freight options, reducing reliance on spot contracts.

Implement ML tools like Zeus Command AI to optimise freight operations and predict future logistics needs.

Predictive Analytics

This AI technology uses past data to forecast issues such as:

- Delivery Delays: Predict delays based on historical trends, traffic, or weather.

- Inventory Optimisation: Prevent stockouts and overstocking by forecasting demand more accurately.

Implement predictive analytics to forecast demand and optimise stock levels, improving efficiency across the supply chain.

Automation

AI-driven automation can streamline:

- Freight Management: Automatically select carriers and manage scheduling.

- Warehouse Operations: Robots can handle inventory, picking, packing, and sorting, reducing errors.

Choose AI tools that integrate seamlessly with your TMS, ERP, and WMS systems for streamlined automation.

Robotics and Autonomous Vehicles

AI-powered robotics and autonomous vehicles, such as drones and self-driving trucks, can enhance:

- Warehouse Efficiency: Robots can retrieve and deliver items automatically.

- Transportation: Autonomous vehicles can lower costs and increase delivery speeds on long-haul routes.

Invest in robotics and explore the use of autonomous vehicles in regions with favourable regulations.

3. Collect and Standardise Data

AI’s effectiveness in logistics depends on clean, structured, and comprehensive data. Disorganised or incomplete datasets lead to inaccurate predictions and inefficiencies. Businesses must aggregate and standardise data from multiple sources, ensuring AI models can process and generate actionable insights.

Start by identifying key data streams, including:

- Shipment Records: Historical and real-time freight movement data from TMS and carrier networks.

- Inventory Levels: WMS data tracking stock availability, turnover rates, and demand fluctuations.

- Operational Metrics: Warehouse efficiency, delivery performance, and cost-per-mile analytics.

- External Variables: Traffic, fuel costs, and weather patterns that impact logistics.

Once identified, data must be normalised to ensure consistency across systems. If AI is to automate decision-making, datasets from ERP, TMS, and WMS must be structured in compatible formats.

Zeus Command AI integrates real-time shipment data and operational analytics to provide clean, standardised inputs for AI models.

4. Implement AI-Powered Demand Forecasting

Accurate demand forecasting is essential for optimising logistics, reducing costs, and preventing stock imbalances. AI-powered models analyse historical sales trends, market fluctuations, and external factors to predict demand patterns with greater precision than traditional forecasting methods.

To integrate AI-driven forecasting:

- Aggregate historical and real-time sales data from ERP and WMS platforms.

- Include external variables like seasonal trends, economic shifts, and supply chain disruptions.

- Deploy machine learning models that continuously refine accuracy based on evolving patterns.

5. Optimise Route Planning with AI

Inefficient routing leads to higher fuel costs, missed delivery windows, and underutilised fleet capacity. AI-driven route optimisation analyses real-time and historical data to determine the most efficient paths for deliveries, reducing transit times and increasing reliability.

To implement AI-powered routing:

- Integrate real-time GPS and traffic data to dynamically adjust delivery routes.

- Use machine learning models to anticipate congestion, road closures, and weather disruptions.

- Factor in vehicle capacity, driver schedules, and delivery priorities for better load distribution.

6. AI-Driven Risk Management

AI can be a game-changer for identifying and mitigating risks in logistics before they disrupt operations. By analysing vast amounts of historical data, external factors (like political instability, natural disasters, or economic shifts), and supply chain fluctuations, AI can predict potential risks and suggest preemptive measures.

To implement AI-driven risk management:

- Risk Identification: Leverage AI to analyse external data sources, such as weather patterns, geopolitical developments, and market trends, to foresee potential risks to logistics operations.

- Predictive Models: Use AI to simulate different risk scenarios (e.g., disruptions in transportation routes, port closures, or strikes) and create risk mitigation strategies.

- Proactive Decision-Making: Deploy AI tools that continuously monitor external variables and adjust logistics strategies in real-time, such as changing routes or selecting alternative suppliers, to minimise disruptions.

7. Automate Freight and Carrier Selection

Selecting the right carriers impacts cost efficiency, service reliability, and delivery speed. Traditional freight selection relies on manual processes and static contracts, leading to higher costs and inconsistent performance. AI-driven carrier selection analyses real-time data to automate and optimise freight assignments.

To implement AI-driven freight automation:

- Use AI to analyse carrier performance metrics (on-time delivery, cost per mile, and service reliability).

- Automate load assignments based on capacity availability, pricing trends, and route efficiency.

- Continuously evaluate carrier contracts to identify cost-saving opportunities and reduce reliance on spot-market rates.

We have built Zeus Command AI to optimise freight and carrier selection by analysing live market rates, performance data, and capacity constraints. Instead of relying on fixed contracts, Zeus dynamically selects the best carrier for each shipment, minimising costs while maintaining service quality.

8. Deploy AI for Warehouse Automation

AI-driven warehouse automation reduces manual errors, optimises inventory flow, and increases fulfilment speed. Traditional warehouses struggle with inefficient picking, stock discrepancies, and labor-intensive processes. AI automates repetitive tasks, enabling warehouses to scale operations without adding excessive labor costs.

To implement AI-powered warehouse automation:

- Deploy AI-driven robotics for picking, packing, and sorting to reduce processing times.

- Use computer vision for inventory tracking, ensuring accurate stock levels and reducing lost inventory.

- Automate replenishment algorithms to maintain optimal stock levels without human intervention.

9. AI for Sustainability

AI can significantly contribute to making logistics operations more sustainable by reducing energy consumption, minimising waste, and optimising resource use. AI-powered tools help businesses optimise their environmental footprint, making supply chains more eco-friendly while maintaining efficiency.

To implement AI for sustainability:

- Energy Optimisation: Use AI to analyse fuel consumption, fleet management, and vehicle routing to reduce carbon emissions and optimise energy use.

- Sustainable Sourcing: Leverage AI tools to analyse suppliers and materials, helping businesses choose eco-friendly alternatives and reducing waste.

- Packaging Optimisation: AI can optimise packaging to reduce material usage and lower transportation costs, further minimising environmental impact.

- Carbon Footprint Tracking: Implement AI-driven platforms to track and reduce the carbon footprint of logistics operations, including vehicle emissions, packaging, and overall supply chain efficiency.

10. Enhance Shipment Tracking and Real-Time Visibility

Real-time shipment tracking reduces delays, lost shipments, and operational blind spots. Traditional tracking relies on static updates from carriers, causing reactive problem-solving instead of proactive issue resolution. AI-powered visibility platforms provide continuous tracking, automated alerts, and predictive disruption management.

To implement AI-driven tracking:

- Deploy IoT sensors and GPS tracking for live shipment monitoring across all transport modes.

- Use AI-driven predictive analytics to anticipate delays and reroute shipments in real time.

- Automate exception handling to minimise disruptions and reduce missed delivery windows.

Zeus Command AI provides end-to-end shipment visibility, aggregating data from carriers, warehouses, and logistics partners into a centralised dashboard. It enables proactive issue resolution, alerting teams before disruptions occur.

Unlock the Full Potential of AI in Logistics With Zeus

AI is transforming logistics by automating workflows, optimising routes, and enhancing real-time decision-making. Companies that leverage AI-driven solutions gain a competitive advantage by reducing costs, improving efficiency, and increasing visibility across their supply chain. To fully capitalise on AI’s potential, businesses need a reliable, scalable platform like Zeus.

Zeus is an AI-powered logistics solution that streamline freight management, optimise carrier selection, and provide real-time tracking insights. With advanced automation and predictive analytics, Zeus helps businesses enhance supply chain efficiency, reduce disruptions, and drive cost savings.

Are you ready to leverage AI for smarter logistics solutions? Request a Demo with Zeus Today.

Trusted By